What is the Best 2-Stroke Oil for Motorcycles in Ethiopia?

The distinctive, high-pitched whine of a two-stroke engine is more than just a sound; it’s the soundtrack to Ethiopian mobility. From the dense, energetic traffic of Addis Ababa’s “Piazza” to the rugged, dusty paths of the Oromia region, these machines are indispensable. They are the workhorses of an entire nation, powering everything from daily commutes and bajaj taxis to small-scale agricultural transport. Their popularity is rooted in a beautiful simplicity: fewer moving parts, a phenomenal power-to-weight ratio, and a mechanical straightforwardness that makes them easier and cheaper to repair than modern four-strokes.

However, this very simplicity belies a critical vulnerability. The lifeblood of a two-stroke engine—its lubricating oil—is also its potential Achilles’ heel. An uninformed choice at the oil shelf can mean the difference between a motorcycle that runs for years and one that suffers a catastrophic seizure in a matter of months. For the Ethiopian rider, navigating this choice is compounded by unique local challenges: pervasive dust, variable fuel quality, high-altitude operation, and a market saturated with counterfeit products. This guide is not just a list of recommendations; it is a deep dive into the science of lubrication, tailored specifically to the Ethiopian context, to empower you with the knowledge to protect your vital investment.

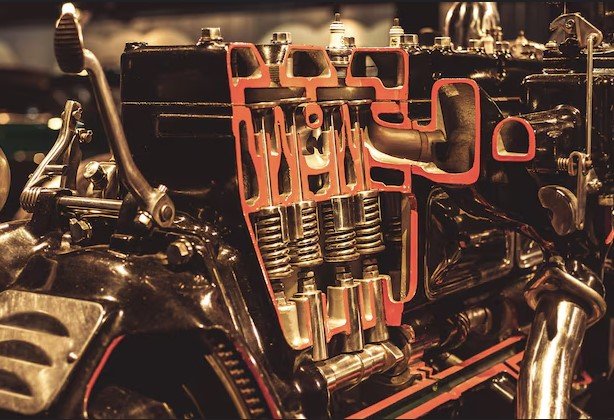

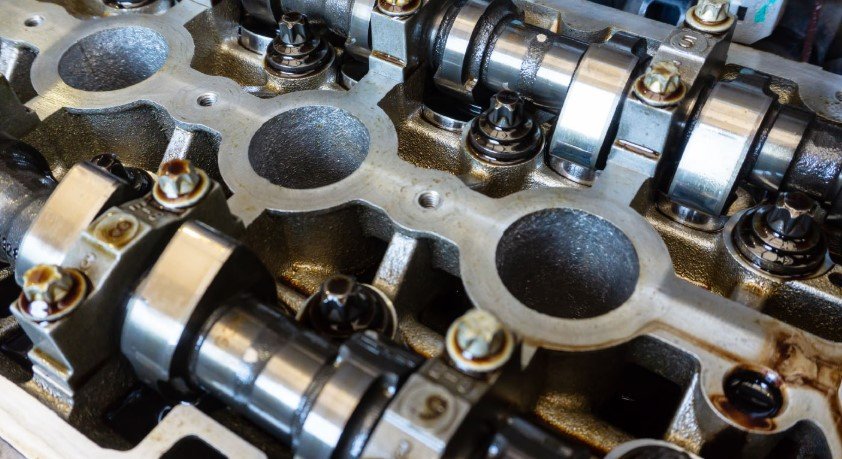

The Beating Heart: A Deep Dive into Two-Stroke Engine Mechanics

To understand why oil is so critical, we must first appreciate the brutal environment inside a two-stroke engine. Unlike a four-stroke engine with a dedicated oil sump that continuously lubricates components, a two-stroke engine performs its lubrication in a single, integrated, and violent process.

The oil is mixed directly with petrol, either in the fuel tank (pre-mix) or via a separate, automated oil injection tank. This mixture is then drawn into the crankcase. Here, the oil must atomize and coat every critical component—the main crankshaft bearings, the connecting rod big-end and small-end bearings, and the cylinder walls—in a protective film before being forced into the combustion chamber and burned alongside the fuel during the power stroke.

This creates a “total loss” lubrication system with non-negotiable demands on the oil:

Simultaneous Lubrication and Combustion: The oil must perform two diametrically opposed functions. First, it must be a tenacious lubricant, clinging to metal surfaces under extreme heat and pressure. Second, it must be a willing participant in combustion, vaporizing completely to leave minimal residue. Low-quality oils fail this balancing act spectacularly, leading to carbon buildup and engine destruction.

High-Temperature Stability: Two-stroke engines run notoriously hot. The oil must resist thermal breakdown, maintaining its viscosity and lubricity to prevent the piston from “scuffing” or welding itself to the cylinder wall—a phenomenon known as piston seizure.

Detergency and Dispersancy: The by-products of combustion, along with any dust that passes the air filter, are highly abrasive. The oil must contain detergent additives to keep these contaminants in suspension and dispersant additives to carry them out through the exhaust port, preventing the formation of harmful sludge and deposits.

The Ethiopian Operating Environment: A Perfect Storm for Engine Wear

Choosing a two-stroke oil in Europe or North America is relatively straightforward. In Ethiopia, the operating conditions add layers of complexity that make the correct choice a matter of engine life or death.

The Ubiquity of Dust: Ethiopian terrain, particularly outside major urban centers, is profoundly dusty. Fine, silica-based dust is one of the most effective abrasives known. While a high-quality, well-oiled air filter is the first defense, some fine particulate will inevitably get past. This dust mixes with the oil-fuel mixture, creating a grinding paste. Only an oil with exceptional film strength and extreme pressure (EP) additives can hope to protect bearing surfaces in this environment.

Fuel Quality Inconsistencies: The octane rating and purity of petrol can vary between stations and regions. Contaminants like water or other impurities can cause the oil to separate from the fuel (“phase separation”), leading to inadequate lubrication. A high-quality oil contains emulsifiers and stabilizers that help it bond with the fuel consistently, even when fuel quality is less than ideal.

High-Altitude Operation: Addis Ababa sits at 2,355 meters above sea level. At these altitudes, the air is thinner, meaning less oxygen enters the engine. To compensate, carburetors tend to run richer (more fuel, less air). A richer mixture can lead to lower combustion temperatures and increased carbon fouling. A clean-burning, synthetic oil is therefore even more critical in high-altitude cities to prevent plug fouling and port blocking.

The Counterfeit Market: This is perhaps the single greatest threat. The lucrative lubricant market is a target for counterfeiters who fill branded bottles with sub-par, often re-refined, base oils with little to no additive package. These fakes provide almost no protection and are a primary cause of premature engine failure. Establishing a trusted supplier is not a convenience; it is a necessity.

Mineral, Semi-Synthetic, or Full Synthetic: A Detailed Technical Breakdown

The base oil composition is the foundation of performance. Understanding these categories is key to making an informed choice.

Mineral Oil: The Economical Baseline

Source: Derived directly from the refining of crude petroleum.

Composition: Consists of hydrocarbon molecules of varying sizes and shapes, which leads to inconsistent performance.

Pros:

Cost-Effective: This is the most significant advantage for riders on a tight budget.

Adequate for Low-Stress Engines: Suitable for older, low-compression engines that were designed to run on these oils.

Cons:

High Carbon Deposits: Tends to leave behind significant carbon, varnish, and sludge. This can clog the critical exhaust port, reducing power and increasing engine temperature.

Poor Thermal Stability: The irregular molecules break down quickly under high heat, leading to rapid viscosity loss and reduced lubrication at high RPMs.

Higher Smoke and Odor: Burns less cleanly, producing more visible blue smoke and a strong, unpleasant smell.

Full Synthetic Oil: The Pinnacle of Performance

Source: Chemically engineered from modified petroleum components or entirely synthesized from other chemical compounds (esters).

Composition: Uniform, designer molecules that are tailored for specific performance characteristics.

Pros:

Exceptional Thermal Stability: Withstands extreme temperatures without breaking down, offering superior protection against piston seizure.

Ultra-Clean Burning: Leaves minimal ash and carbon deposits, keeping the piston crown, ring grooves, and exhaust port clean for maximum power and efficiency.

Superior Lubricity: Provides a stronger, more resilient lubricating film, drastically reducing engine wear, especially in dusty conditions.

Low Smoke and Foul-Reduction: Dramatically reduces visible smoke and prevents spark plug fouling.

Cons:

Higher Cost: The advanced manufacturing process makes it the most expensive option.

Potential for Incompatibility: In very old engines with certain types of seals, synthetics can cause leaks (this is rare with modern formulations).

Semi-Synthetic Oil: The Strategic Compromise

Source: A precise blend of mineral and synthetic base oils, augmented with a solid additive package.

Composition: Typically a 70/30 or 60/40 mix of mineral to synthetic base stocks.

Pros:

Excellent Value: Offers a significant portion of synthetic’s performance benefits at a price point closer to mineral oil.

Balanced Performance: Provides better deposit control and wear protection than mineral oil, making it an ideal “sweet spot” for most modern commuter and light-commercial two-strokes in Ethiopia.

Wide Compatibility: Safe for use in virtually any two-stroke engine.

Cons:

Not Top-Tier: It does not offer the ultimate level of protection and cleanliness of a full ester-based synthetic.

Comparative Analysis at a Glance

The following table provides a direct comparison of the three oil types in the context of Ethiopian riding conditions:

Feature Mineral Oil Semi-Synthetic Oil Full Synthetic Oil Engine Cleanliness Poor. High carbon & deposit formation. Good. Significant improvement over mineral. Excellent. Keeps engine virtually deposit-free. Wear Protection (Dust) Fair. Weak film strength fails under abrasive load. Good. Robust additive package helps combat dust. Superior. Exceptional film strength protects bearings. High-Temp Stability Poor. Breaks down quickly, risk of seizure. Good. Stable under normal to high stress. Excellent. Designed for extreme heat and RPM. Smoke & Emissions High. Visible smoke and strong odor. Moderate. Noticeably cleaner than mineral. Very Low. Minimal visible smoke and odor. Cost & Value Lowest upfront cost, poorest long-term value. Best balance of cost and performance. Highest upfront cost, best long-term engine protection. Ideal Use Case Vintage, low-RPM engines where cost is the sole driver. The recommended choice for most Ethiopian commuter motorcycles. High-performance bikes, intense load conditions (e.g., laden bajaj), and riders seeking maximum longevity.

The Local Champion: A Closer Look at Afro Oil Lubricants and What to Look For

In this complex landscape, the emergence of local lubricant specialists is a promising development. A company like Afro Oil Lubricants, with its focus on the East African market, presents a compelling proposition. The advantages of a robust local brand are significant: consistent supply chain logistics reducing stockouts, and the potential for product formulations that are specifically engineered for the region’s fuel quality, climate, and dust levels.

When evaluating Afro Oil Lubricants, or any brand claiming local expertise, a rider must move beyond marketing and look for tangible, technical proof of quality. The bottle and technical data sheet (which a reputable supplier should be able to provide) must answer these questions:

What is the API Certification? The American Petroleum Institute (API) classifies two-stroke oils. The current minimum standard for most motorcycles is “API TC.” This certifies performance in lubricity, detergency, and anti-scuffing. Do not purchase an oil without a clear API classification.

What is the JASO Rating? The Japanese Automotive Standards Organization (JASO) standard is more stringent and specific. The grades are FA, FB, FC, and FD, with FD being the highest.

JASO FC: “Low Smoke” oil.

JASO FD: “Low Smoke and High Detergency” oil. A JASO FD rating is a powerful indicator of a superior, clean-burning oil that will keep your engine running strong.

Is it Low-Ash? Look for the terms “Ashless” or “Low-Ash.” Ash is a metallic residue (from additives like calcium and zinc) that remains after combustion. In a two-stroke, this ash can form hard, abrasive deposits on the piston crown and in the ring grooves, leading to hot spots and ring sticking.

The growing market presence of Afro Oil Lubricants suggests they are meeting a need for a accessible, quality-conscious product. The commitment of Afro Oil Lubricants to achieving these international standards is what will build long-term trust with the discerning Ethiopian rider.

The Non-Negotiables: Mixing, Maintenance, and Final Recommendations

The best oil in the world is useless if mixed incorrectly. Precision is everything.

The Golden Rule: Use a Measuring Bottle. Never, ever “glug” oil directly from the bottle into your fuel tank. Use a dedicated two-stroke mixing bottle with clear ratio markings (e.g., 1:50, 1:33). Your owner’s manual is the final authority on the ratio.

The Mixing Procedure:

Add the precise amount of oil to an empty mixing bottle.

Add a small amount of petrol, seal the bottle, and shake it violently for 30 seconds. This creates a pre-mix emulsion.

Add the remaining petrol and shake again thoroughly. This two-stage process ensures a perfectly homogenous mixture that will not separate.

Final Verdict and Recommendation:

After weighing all the factors—the harsh operating environment, the prevalence of dust, the risk of counterfeit products, and the need for long-term engine health—the optimal choice for the vast majority of Ethiopian motorcycle owners is a high-quality semi-synthetic oil meeting JASO FD or at least API TC specifications.

This choice provides the perfect balance:

It offers dramatically better protection and cleanliness than mineral oil, directly combating the challenges of dust and variable fuel.

It is significantly more affordable than full synthetic, making it a sustainable, cost-effective choice for daily use.

It delivers the clean-burning performance needed for reliable operation at the high altitudes of the Ethiopian highlands.

Whether you choose an international brand or a proven local specialist like Afro Oil Lubricants, the key is to be an informed consumer. Your motorcycle is more than a machine; it is your livelihood and your freedom. By investing in the right oil and mixing it with care, you are not just filling a tank—you are ensuring that the distinctive buzz of your two-stroke engine continues to echo for miles and years to come.

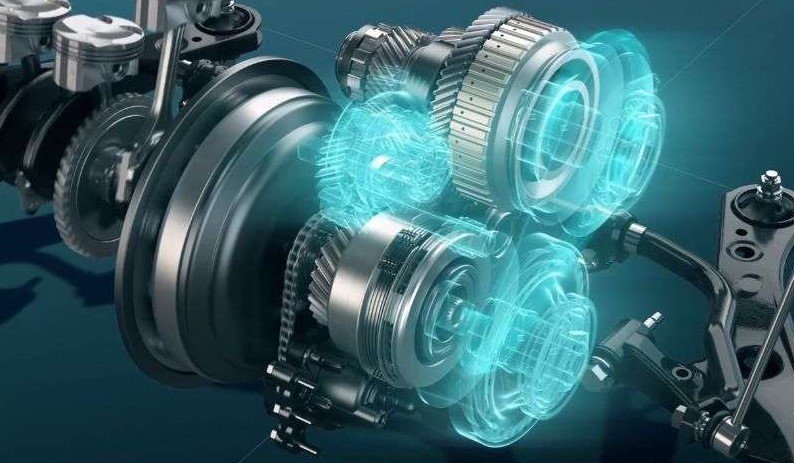

How to Find the Right Transmission Oil in Ethiopia?

How to Find the Right Transmission Oil in Ethiopia? Discover More In the dynamic landscape of Ethiopian transportation, where vehicles traverse everything from the bustling

How to Choose the Most Durable Diesel Engine Oil in Ethiopia?

How to Choose the Most Durable Diesel Engine Oil in Ethiopia? Discover More In Ethiopia’s demanding landscape, where rugged terrain, heavy loads, and fluctuating temperatures

Viscosity Grades Explained: Choosing the Right Hydraulic Oil in Ethiopia

Viscosity Grades Explained: Choosing the Right Hydraulic Oil in Ethiopia Discover More From the expansive agricultural fields of the Oromia region to the bustling construction

Boost Mileage & Power: Top Fuel Injector Cleaners in Ethiopia’s Climate

Boost Mileage & Power: Top Fuel Injector Cleaners in Ethiopia’s Climate Discover More Is your car feeling sluggish on the climb to Entoto? Have you

Sourcing Premium Group III Base Oils in Ethiopia: A Strategic Supplier Landscape Analysis

Sourcing Premium Group III Base Oils in Ethiopia: A Strategic Supplier Landscape Analysis Discover More Ethiopia stands at a pivotal moment in its economic development.

Struggling to Source Reliable Base Oil Group II in Ethiopia? Here’s Your Solution

Struggling to Source Reliable Base Oil Group II in Ethiopia? Here’s Your Solution Discover More The Ethiopian industrial landscape is booming. From manufacturing and agriculture

Affordable

Affordable Poor performance in extreme heat/cold

Poor performance in extreme heat/cold